CNC Lathe Made Simple

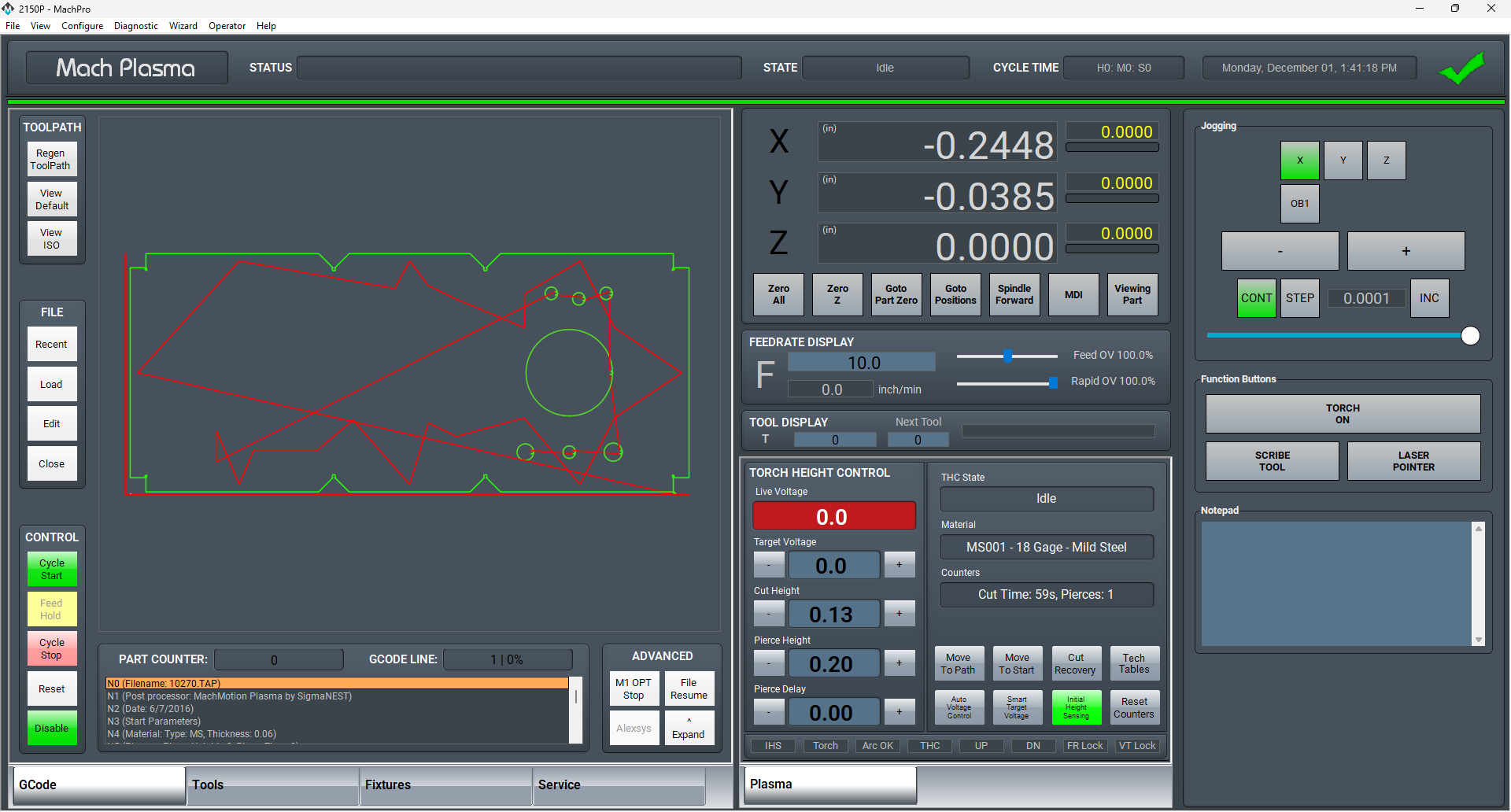

MachPro brings industrial-grade performance to every lathe

The simplicity makers love and the reliability production teams depend on. From quick setup to stable runtime, every detail helps you cut, thread, and finish with confidence.

Why Choose MachPro

Built on real shop feedback — engineered for smooth motion, fast setup, and repeatable accuracy.

Industry‑Standard

G/M Codes

Compatible with common lathe cycles (roughing, finishing, threading)

Conversational Programming & Canned Cycles

Face, turn, groove, bore, and thread without writing code.

File Resume

Restart precisely where you left off after a stop or power loss.

Fast Tool Touch-Off

& Offsets

Quick, reliable tool setup and management.

Customize MachPro to fit how you run your shop — not the other way around

- Add on-screen tools like a calculator or custom job widgets.

- Place your favorite functions directly on the main screen.

- Configure the screen in just 5 clicks — no coding, no hassle.

CCS (Constant Surface Speed)

Consistent chip load and surface finish

Part Counter

Automatic run tracking and job totals

Threading Cycles

Multi-pass, finish, and taper support

Probing

Part location, tool setting, and in-process checks

Integrated Machine Options

Gear shifters, tool changers, and safety I/O

Your Machine Your Build

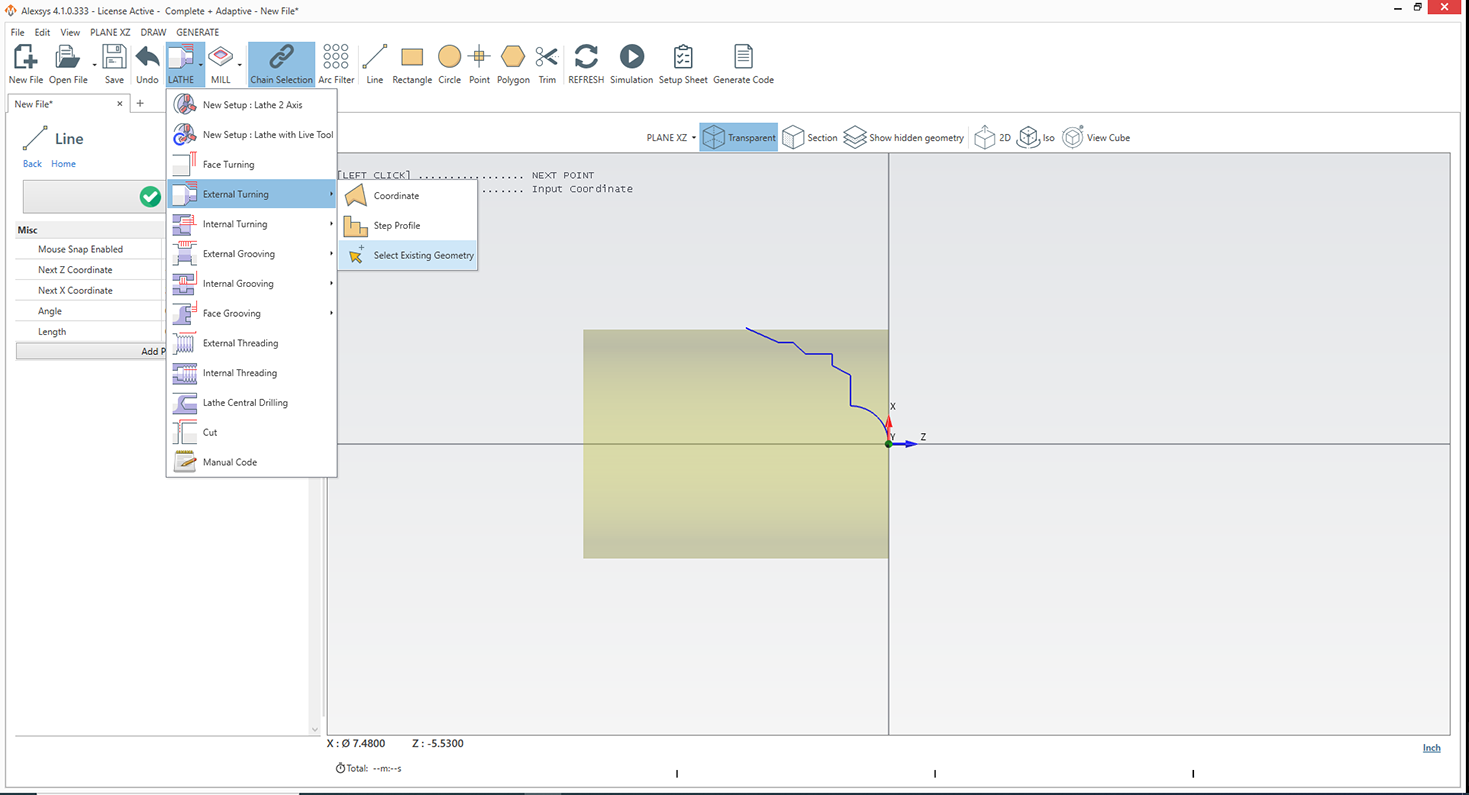

Alexsys Lathe (Optional)

Quickly program common parts without GCode programming.

- Intuitive graphical interface for creating common operations: Turning, grooving, threading, center drilling, cut-off operation, positioning, custom G-codes.

- DXF/DWG import or basic CAD editor to save you time.

- 3D solid simulation

- Thread database for the most used thread tables.

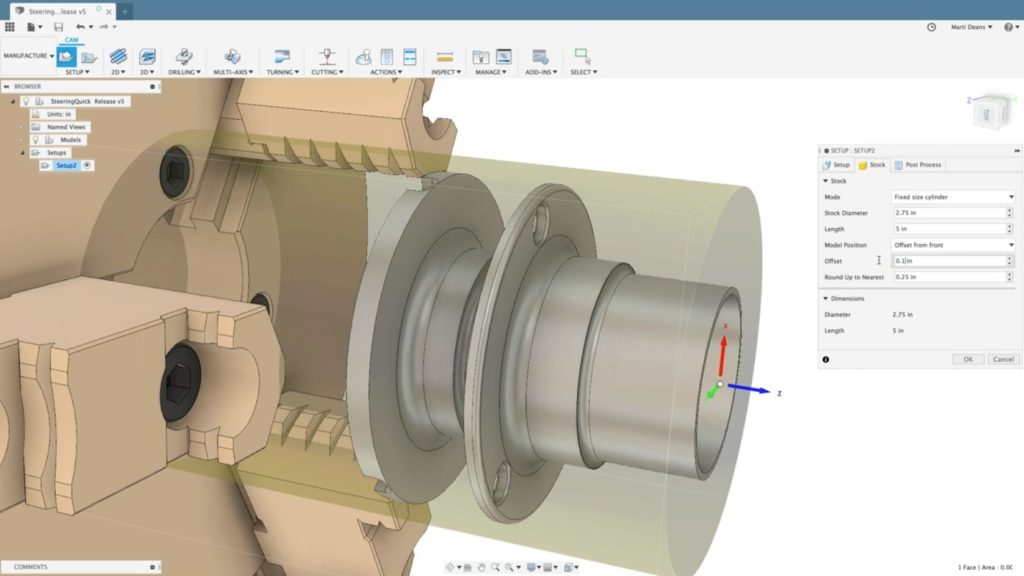

Cad/CAM Integration

MachPro runs Fanuc-style G-Code, making it compatible with leading CAM packages.

Check with your CAD/CAM provider for available MachPro post processors.

Logos of CadCAM packages

- Fusion 360

- MasterCAM

- BobCAD‑CAM

- GibbsCAM

- RhinoCAM

Ready to Turn with Confidence?

Experience the precision, flexibility, and freedom of MachPro CNC Lathe Control — engineered for machinists, toolmakers, and manufacturers who demand accuracy, speed, and reliability in every part they produce.